Abashinwa babigize umwuga Ubushinwa S45c SAE1045 C45 Amashanyarazi ashyushye ya Carbone

Fata inshingano zuzuye kugirango uhuze ibyifuzo byabakiriya bacu;kugera ku majyambere ahoraho dutezimbere iterambere ryabakiriya bacu;ube umufatanyabikorwa wanyuma wa koperative uhoraho wabakiriya kandi wongere inyungu zabakiriya kubashinwa babigize umwuga Ubushinwa S45c SAE1045 C45 Amashanyarazi ashyushye ya Carbone Steel Sheet, Twizera ko mubwiza burenze ubwinshi.Mbere yo kohereza hanze umusatsi hari igenzura rikomeye ryo kugenzura ubuziranenge mugihe cyo kuvura nkuko ubuziranenge mpuzamahanga bubyerekana.

Fata inshingano zuzuye kugirango uhuze ibyifuzo byabakiriya bacu;kugera ku majyambere ahoraho dutezimbere iterambere ryabakiriya bacu;ube umufatanyabikorwa wanyuma wa koperative uhoraho wabakiriya kandi wongere inyungu zabakiriya kuriUrupapuro rw'icyuma, Urupapuro rushyushye, Ikipe yacu izi neza ibyifuzo byisoko mubihugu bitandukanye, kandi irashobora gutanga ibicuruzwa byiza nibisubizo byiza kubiciro byiza kumasoko atandukanye.Isosiyete yacu yamaze gushyiraho itsinda ry'inararibonye, rihanga kandi rifite inshingano zo guteza imbere abakiriya bafite ihame-ryinshi.

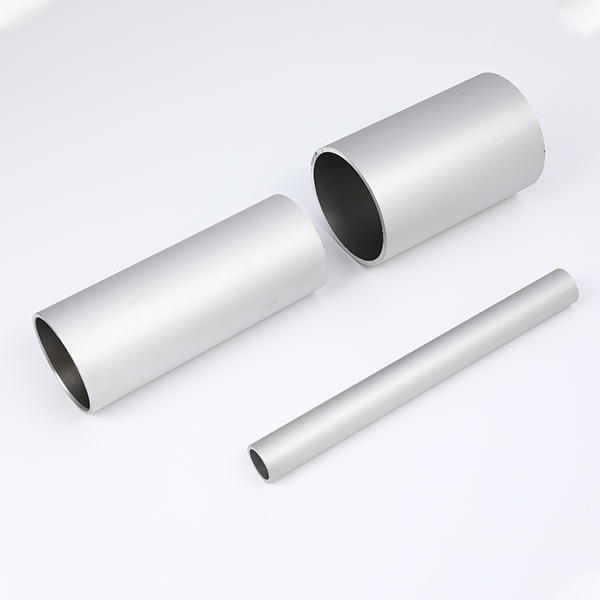

Inkoni ya pneumatike hydraulic piston inkoni nayo yitwa chrome isize inkoni.Ninkoni ifite ubuso buvurwa no gusya bidasanzwe hamwe na plaque ya chrome.Ikoreshwa cyane muri silinderi zitandukanye, silindiri ya hydraulic, gupakira, gukora ibiti, kuzunguruka, imashini zicapa no gusiga amarangi, ibice bipfa gupfa nibindi bikoresho byogukwirakwiza byikora kubera ubukana bwabyo, bishobora kwongerera igihe cyimirimo yimashini isanzwe nibikoresho bisanzwe.

Twafashe imbeho ikonje, gushushanya no gusya kugirango dukore pneumatike silinderi hydraulic piston inkoni, intego zose za tekiniki zujuje ubuziranenge bwigihugu.

Ibisobanuro birambuye

Ibikoresho: CK45 (GB / T699-1999)

Ibisobanuro bya mashini:

Imbaraga zingana (Mpa): ≥600N / mm2

0,2 Gutanga umusaruro (Mpa): ≥355N / mm2

Kurambura: min.16%

Ubushyuhe bwa Chrome: φ mm 20mm≥15μm , kuva kuri 20mm > 20μm

Ubukonje: Ra < 0.2

Ubukomezi bwa Chrome Layeri: 850HV-1050HV

Ubworoherane bwa Diameter: f7, f8

Kugororoka: <0.1um / 1000mm

Ovality: < 1/2 kwihanganira diameter

Isuzuma rya Corroseston Ikizamini: ISO 10289: 1999, IDT

Diameter yo hanze: 3-120mm (GCr15) 3-40m (SUS440C)

Imiterere yo gutanga: Bisanzwe, Induction Harden, Q + T.

Imbonerahamwe yimiti

| UMURIMO W'IMIKORESHEREZE (%) | |||||||

| Ibikoresho | C% | Mn% | Si% | S% | P% | V% | Cr% |

| <= | |||||||

| CK45 | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | 0.035 | 0.035 | ||

| ST52 | <= 0.22 | <= 1.6 | <= 0.55 | 0.035 | 0.035 | 0.10-0.20 | |

| 20MnV6 | 0.16-0.22 | 1.30-1.70 | 0.1-0.50 | 0.035 | 0.035 | ||

| 42CrMo4 | 0.38-0.45 | 0.60-0.90 | 0.15-0.40 | 0.03 | 0.03 | 0.90-1.20 | |

| 4140 | 0.38-0.43 | 0.75-1.0 | 0.15-0.35 | 0.04 | 0.04 | 0.80-1.10 | |

| 40Cr | 0.37-0.45 | 0.50-0.80 | 0.17-0.37 | 0.80-1.10 | |||

| Diameter | Ibiro | Ubworoherane | Ubworoherane | Ubworoherane |

| mm | Kg / m | f7 (μm) | f8 (μm) | h6 (μm) |

| 6 | 0.22 | -10-22 | -10-28 | 0-9 |

| 8 | 0.39 | -13-28 | -13–35 | 0-9 |

| 10 | 0.62 | -13-28 | -13–35 | 0–11 |

| 12 | 0.89 | -16–34 | -16–43 | 0–11 |

| 16 | 1.58 | -16–34 | -16–43 | 0–11 |

| 18 | 2.00 | -16–34 | -16–43 | 0–13 |

| 20 | 2.47 | -20–41 | -20–53 | 0–13 |

| 22 | 2.99 | -20–41 | -20–53 | 0–13 |

| 25 | 3.86 | -20–41 | -20–53 | 0–13 |

| 28 | 4.84 | -20–41 | -20–53 | 0–13 |

| 30 | 5.55 | -20–41 | -20–53 | 0-16 |

| 32 | 6.32 | -25–50 | -25–64 | 0-16 |

| 36 | 8.00 | -25–50 | -25–64 | 0-16 |

| 38 | 8.91 | -25–50 | -25–64 | 0-16 |

| 40 | 9.87 | -25–50 | -25–64 | 0-16 |

| 45 | 12.49 | -25–50 | -25–64 | 0-16 |

| 50 | 14.22 | -25–50 | -25–64 | 0–19 |

| 55 | 15.43 | -30–60 | -30–76 | 0–19 |

| 60 | 18.66 | -30–60 | -30–76 | 0–19 |

| 65 | 26.07 | -30–60 | -30–76 | 0–19 |

| 70 | 30.23 | -30–60 | -30–76 | 0–19 |

| 75 | 34.71 | -30–60 | -30–76 | 0–19 |

| 80 | 39.49 | -30–60 | -30–76 | 0-22 |

| 85 | 44.58 | -36–71 | -36–90 | 0-22 |

| 90 | 49.98 | -36–71 | -36–90 | 0-22 |

| 95 | 55.68 | -36–71 | -36–90 | 0-22 |

| 100 | 61.70 | -36–71 | -36–90 | 0-22 |

Ni ubuhe buryo bwo kwihanganira f7 na f8:

Urwego rwo kwihanganira f8 nini kuruta urwa f7, kandi kwishyiriraho biterwa nurwego rwo kwihanganira umwobo.Kurugero, iyo ingano shingiro ari 10-18, f8 (-0.016, -0.034), f7 (-0.016, -0.027), gutandukana kwihanganira byombi ni kimwe, intera ya f7 iba nto, kandi byemewe urwego rwo kwishyiriraho rukwiye ni ruto.

Umusaruro utemba

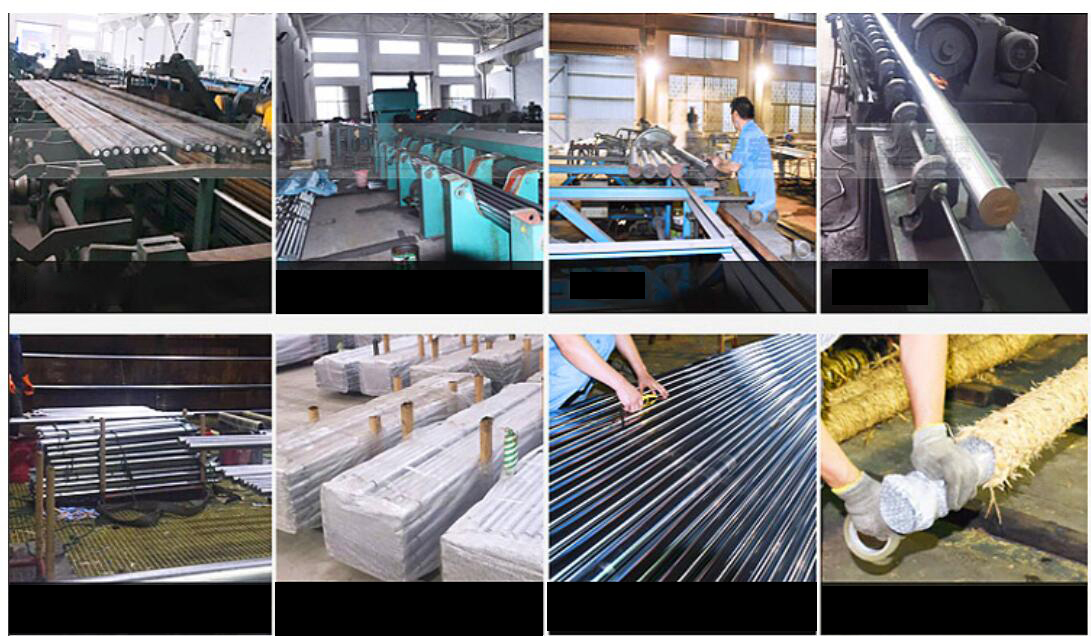

Intambwe 1: Gukuramo / Ubukonje Bishushanyije:

Igishushanyo gikonje nubuhanga bwo gutunganya pneumatic silinderi piston inkoni.Kuri pneumatike silinderi ikomeye ya chrome isize inkoni, gushushanya gukonje bivuga gushushanya ukurikije ubushyuhe busanzwe kugirango ugere kumiterere runaka hamwe nubukanishi.Ugereranije no gushyuha, ibicuruzwa bikonje bikonje bifite ibyiza byo murwego rwo hejuru kandi birangiye neza.

2 Intambwe: Kugororoka

Iyi ntambwe turashobora kwemeza neza ko inkoni ikomeye ya chrome ikozwe neza igororotse bihagije.Nibyingenzi cyane, mugihe ushyizemo imbere silinderi ya pneumatike.Uburinganire busanzwe ni 0.2mm / m.

3 Intambwe: Kubaha

Gutunganya icyubahiro nuburyo bunoze bwo gutunganya butuma pneumatike ya silinderi piston inkoni igera kubintu bisobanutse neza, hejuru yubuzima bwiza no kuramba.Irashobora kunoza neza uburinganire bwukuri, imiterere yukuri no kugabanya agaciro ka Ra, ariko ntishobora kunoza imyanya yumwobo nubundi buso.

4 Intambwe: Inkoni y'icyuma

Gusiga bivuga gukoresha imashini, imiti cyangwa amashanyarazi kugirango ugabanye ubukana bwubuso bwa pisiyumu ya pisitori ya piston kugirango ubone ubuso bwiza kandi bworoshye.Nugukoresha ibikoresho byo gusya hamwe nuduce duto twa abrasive cyangwa ibindi bitangazamakuru byogosha kugirango uhindure ubuso bwa pneumatic silinderi piston inkoni

Intambwe 5: Gushiraho Chrome

Isahani ya Chrome bivuga igikorwa cyo gufata chromium nkigifuniko ku nkoni ikomeye ya chrome yashizwemo.

Igice cya chromium gishyizwe hamwe gifite ubukana buhanitse cyane, kandi ubukana bwacyo burashobora gutandukana mugihe kinini cya 400-1200HV ukurikije ibigize igisubizo hamwe nibisabwa.Igice cya chrome cyometseho gifite ubushyuhe bwiza.Iyo ushyutswe munsi ya 500 ℃, nta mpinduka igaragara muburabyo no gukomera.Ubushyuhe buzatangira okiside no guhindura ibara mugihe ubushyuhe buri hejuru ya 500 ℃, kandi ubukana buzagabanuka iyo buri hejuru ya 700 ℃.Coefficient de fraisation ya chrome layer ni nto, cyane cyane coefficente yumye yumye, niyo yo hasi cyane mubyuma byose.Kubwibyo, igipande cya chrome gifite plaque irwanya kwambara neza.

Ikibumbano cya chromium gifite imiti ihamye.Nta ngaruka igira muri alkali, sulfide, aside nitricike na acide nyinshi kama, ariko irashobora gushonga muri acide pneumatike (nka acide pneumatike) na acide sulfurike ishyushye.Mu mucyo ugaragara, urumuri rwa chromium rugera kuri 65%, ruri hagati ya silver (88%) na nikel (55%).Kuberako chromium idahindura ibara, irashobora gukomeza kugaragariza igihe kirekire kandi iruta ifeza na nikel.

6 Intambwe: Chrome isize inkoni Polishing nyuma yo kuyisiga

Amashanyarazi no gusya: nuburyo bubiri butandukanye bwo gutunganya hejuru yibyuma nibindi bikoresho.Iyambere ni imiti ivura, naho iyanyuma ni imiti.

Amashanyarazi: Inzira yo gukoresha electrolysis kugirango uhuze igice cya firime yicyuma hejuru yicyuma cyangwa ibindi bikoresho.Irashobora gukumira ruswa, kunoza imyambarire, gutwara amashanyarazi, kwerekana no kongera ubwiza.

Gusiga: Koresha ibikoresho byoroshye byo gusya hamwe nuduce duto duto cyangwa ibindi bitangazamakuru bisiga kugirango uhindure ubuso bwakazi.Kuringaniza ntibishobora kunoza uburinganire bwukuri cyangwa geometrike yibikorwa byakazi, ariko bigamije kubona ubuso bworoshye cyangwa indorerwamo.

7 Intambwe: Ikigereranyo cyiza cya Chrome

Inkoni ya piston yagiye ikorwa na electroplating na polishinge akenshi iherekezwa nudusimba twinshi nka pome ya chrome na pitingi.Ingano nubunini bwiyi nenge bigira ingaruka kumikorere ya piston.Kugabanya ingaruka ziyi nenge ku nkoni ya piston, kuruhande rumwe, mukuzamura ireme ryibikoresho fatizo, kunoza ikoranabuhanga ryo gutunganya, no kugabanya kugaragara kwinenge;kurundi ruhande, birakenewe kumenya neza inenge zisahani nyuma yuburyo bwo gusya kugirango hirindwe ibicuruzwa bitujuje ibyangombwa kuva mu ruganda.Ba injeniyeri ba Autoair bamenya gutahura inenge bifashishije ubumenyi bwa siyanse yubumenyi

8 Intambwe: Gupakira

Ibibazo:

Q1: Inkoni ya piston ya pneumatike ni iki?

Igisubizo: Inkoni ya piston nikintu cyibanze kandi gikomeye muri buri silinderi ya hydraulic cyangwa pneumatike.Inkoni ya piston mubusanzwe ni uburebure bwakorewe uburebure bwa chrome ikozwe mu mbeho ikonje ikonje ikohereza imbaraga zakozwe na piston mugice cyimashini ikora akazi.

Q2: Ni irihe hame rya pneumatike silinderi piston inkoni?

Igisubizo: Pistumatike ya pneumatike muri silinderi ifite imbaraga zo gukurura cyangwa gukurura imbaraga zatewe numuvuduko wikirere, kandi igakora muburyo butaziguye inkoni ya pisitori ya pisitori ya piston ihujwe na piston, hanyuma inkoni ya pisitori ya pisiyonike ihujwe nakazi ko gukora kugirango yimuke inyuma n'inyuma.

Q3: Nibihe bikoresho bibisi bya pneumatike ya pisitori ya piston

Igisubizo: Mubisanzwe, pneumatic silinderi piston inkoni ya pneumatike ya pneumatike izahitamo 45 # ibyuma nkibikoresho fatizo.Niba silinderi yakozwe ikeneye gukoreshwa mubidukikije bidasanzwe, ibyuma 304 bidafite ingese nabyo birashobora gukoreshwa

Q4: Kuki uhitamo 45 # ibyuma nkibikoresho fatizo

Igisubizo: 45 # ibyuma nicyuma cyiza cya karubone cyubatswe nicyuma gito kandi gukata byoroshye.Nyuma yo kuzimya, ubukana bwacyo burashobora kugera kuri 45-52HRC.Kandi irashobora kandi kugira imikorere myiza yo gukata hamwe nimbaraga zisumba izindi, ubukana nibindi bikoresho byuzuye byubukanishi, kubwibyo rero nikimwe mubikoresho bisanzwe bikoreshwa mubice bya shaft.

Q5: Nubuhe buryo bwo gutunganya inkoni ya piston ya pneumatike?

Igisubizo: Kugirango ubone ubuziranenge bwimashini ihamye, kugorora intoki inkoni ya piston ntabwo byemewe nyuma yo gutangira.Kubwibyo, inzira yo kugorora igomba gukorwa mbere yo kuyitunganya.Bitewe n'ubukomezi buke bw'igikorwa, guhindukira gukabije no guhinduka neza bigomba gukorwa mugihe cyo gutunganya kugirango tunonosore neza.Uburyo bwakazi bwinkoni ya piston ni ugusubirana umurongo.Kugirango uzamure ubuzima bwa serivisi yinkoni ya piston, hejuru igomba kuba ifite chrome-isa kugirango irusheho gukomera no kwambara.Nyuma ya plaque ya chrome, ubuvuzi bwa polishinge burasabwa kugirango ubone hejuru yubuso bukabije, kugabanya ibintu byo guterana amagambo, no kunoza imikorere.Kubera ko uburyo bwo gusya butagira ingaruka hafi ya diametre yinyuma yinkoni ya piston, igihangano gikeneye kugera kumurongo wo hejuru mbere yo gushiramo chrome.Niyo mpamvu, birakenewe kongeramo uburyo bwiza bwo gusya mbere yo gutunganya chrome (gusya neza birashobora no kunoza ubuso bwa chromium.).Ukurikije isesengura ryavuzwe haruguru, uburyo bunoze bwo gutunganya inkoni ya piston ni: kugorora-guhindagurika-guhinduka neza-gusya neza-gusya-chrome isahani.

Q6: Ni ubuhe buryo bwo gusya inkoni ya piston pneumatike

Igisubizo: Mugihe cyo guhinduka, umwobo wo hagati ufite uruhare rwo guhagarara bizerekana urwego runaka rwo kwambara.Kugirango hamenyekane ihame rihuriweho n'ibipimo, umwobo wo hagati ugomba gutemwa mbere yo gusya kugirango ubuziranenge butungwe.Mugihe cyo gusya, gusya kwipimisha bigomba gukorerwa kumuzenguruko winyuma hafi yimpera yambere, kandi gusya inkoni ya piston birashobora gukorwa gusa mugihe ikibazo cyo kwiruka cyujuje ibisabwa.Usibye kunoza uburinganire buringaniye, uburyo bwiza bwo gusya bugomba no kubona hejuru yubuso buringaniye hejuru yimashini kugirango hongerwe isano ya ion ya chromium mugihe cya electroplating.Kugirango umenye neza ko umubyimba wa chromium ushyizeho urwego rwa piston ya nyuma ya piston imwe, uburinganire bwubuso nyuma yo gusya neza bugomba kuba hafi yubuso bwakorewe nyuma yo gushiramo chromium no gusya.Niba ubuso bwubuso bwinkoni ya piston busabwa kuba hejuru, nka Ra <0.2 μ mm, bigomba kuba hasi neza.Ongeramo super nziza yo gusya cyangwa gusya nyuma yo gusya.

Fata inshingano zuzuye kugirango uhuze ibyifuzo byabakiriya bacu;kugera ku majyambere ahoraho dutezimbere iterambere ryabakiriya bacu;ube umufatanyabikorwa wanyuma wa koperative uhoraho wabakiriya kandi wongere inyungu zabakiriya kubashinwa babigize umwuga Ubushinwa S45c SAE1045 C45 Amashanyarazi ashyushye ya Carbone Steel Sheet, Twizera ko mubwiza burenze ubwinshi.Mbere yo kohereza hanze umusatsi hari igenzura rikomeye ryo kugenzura ubuziranenge mugihe cyo kuvura nkuko ubuziranenge mpuzamahanga bubyerekana.

Abashinwa b'umwugaUrupapuro rw'icyuma, Urupapuro rushyushye, Ikipe yacu izi neza ibyifuzo byisoko mubihugu bitandukanye, kandi irashobora gutanga ibicuruzwa byiza nibisubizo byiza kubiciro byiza kumasoko atandukanye.Isosiyete yacu yamaze gushyiraho itsinda ry'inararibonye, rihanga kandi rifite inshingano zo guteza imbere abakiriya bafite ihame-ryinshi.